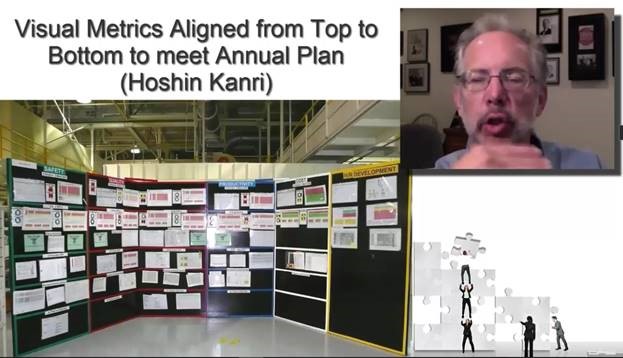

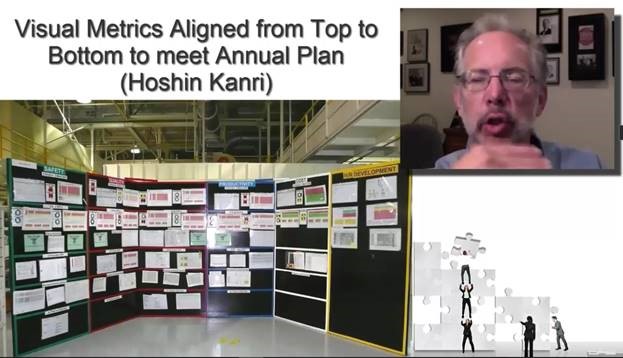

Vertical and Horizontal Alignment

The following article represents one percent of the information in the book, Developing Lean Leaders at All Levels, by Jeff Liker and George Trachilis. The

The following article represents one percent of the information in the book, Developing Lean Leaders at All Levels, by Jeff Liker and George Trachilis. The

The following article is inspired by the book, Developing Lean Leaders at All Levels, by Jeff Liker and George Trachilis. CREATE THE VISION AND THE CAPABILITY

The following article is inspired by the book, Developing Lean Leaders at All Levels, by Jeff Liker and George Trachilis. The teaching objectives for this section